Giải pháp cắt bọt thông minh dao dao dao dao dao dao dao dao dao dao dao dao dao dao dao dao dao dao dao hai CNC tiên tiến cho các ngành công nghiệp đồ nội thất, bao bì và đồ chơi

Mô tả sản phẩm

CNC dao rung đôi: cách mạng chính xác trong cắt bọt biển

Trong làn sóng công nghiệp hiện đại theo đuổi hiệu quả và độ chính xác cực kỳ, lĩnh vực cắt bọt biển đã mở ra một nhà đổi mới hiệu quả và chính xác -Máy cắt bọt biển dao rung hai lần CNC.

Nó hoàn toàn định hình lại kích thước cắt của vật liệu bọt biển với trí tuệ kỹ thuật số và rung động tần số cao. Công nghệ CNC: sản xuất chính xác được điều khiển kỹ thuật số.

Lực thúc đẩy cốt lõi của thiết bị này đến từ công nghệ CNC tiên tiến (kiểm soát số máy tính).

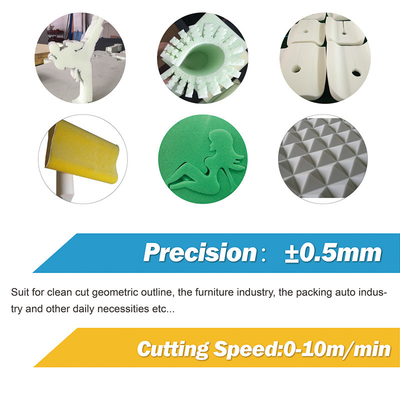

Các kỹ sư chỉ cần nhập các mô hình ba chiều phức tạp vào hệ thống, và bộ não CNC mạnh mẽ có thể ngay lập tức phân tích và chuyển đổi chúng thành các hướng dẫn cắt chính xác.This digital control completely abandons the randomness of traditional manual cutting and the limitations of template processing - each knife strictly follows the preset trajectory to ensure that batch products have perfect millimeter-level consistency, và các hình dạng hình học phức tạp cũng có thể được hình thành chính xác trong một thời gian.

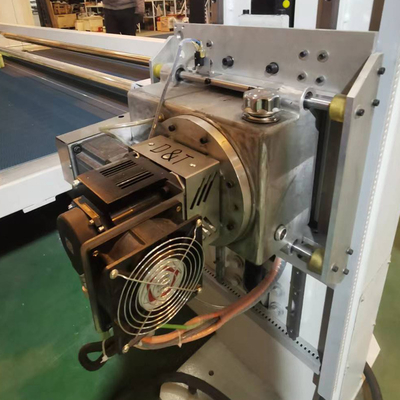

Vibration tần số cao của dao đôi: nghệ thuật cắt chính xác

Các thực thi cốt lõi của độ chính xác này là độc đáo cao tần số hệ thống dao rung đôi. Hai lưỡi dao đặc biệt tương ứng và rung nhẹ ở một tốc độ cực cao,giống như một chiếc dao dao không bóng tối.Sự chuyển động vi sóng tần số cao này làm giảm đáng kể sức đề kháng cắt, cho phép lưỡi dao thâm nhập vào mô bọt biển nhẹ nhàng và trơn tru.

Ưu điểm của nó rất quan trọng:

Bề mặt cắt mịn như gương:Nói lời tạm biệt với rách thô, đường cắt ngang mịn màng và tinh tế, và chất lượng của sản phẩm hoàn thành được cải thiện đáng kể.

Các đường cong phức tạp dễ dàng xử lý:Ngay cả các đường cong mỏng, rãnh hoặc góc sắc nét có thể được theo dõi chính xác và dễ dàng điều khiển bằng dao rung hai.

Hiệu quả và bền:Cắt rung làm giảm tổn thất ma sát, kéo dài tuổi thọ của lưỡi và có khả năng hoạt động liên tục tuyệt vời.

Từ gối thoải mái cho đồ nội thất cao cấp, các bộ phận chính xác cho nội thất xe hơi, đến hỗ trợ tùy chỉnh cho bao bì y tế,Máy cắt dao rung hai lần CNC đang trở thành một lực lượng vô hình để thúc đẩy nâng cấp công nghiệp với độ chính xác và hiệu quả kỹ thuật số vô songNó không chỉ là một công cụ cắt, mà còn là một lưỡi dao tương lai định hình lại tiêu chuẩn chính xác của chế biến bọt biển với sự khôn ngoan của CNC.

Parameter sản phẩm

| Loại |

|

DTC-SD2012 |

| Max. Kích thước sản phẩm |

|

3000*2200*1250mm |

| Lưỡi cắt ngang |

|

2300*3*0,5mm |

| Lưỡi cắt dọc |

|

2300*3*0,5mm |

| Hệ thống điều khiển |

|

Máy tính công nghiệp + Windows XP với D & T Profiler |

| Tốc độ cắt |

|

0 ~ 10m/min (được điều chỉnh) |

| Sức mạnh |

|

9.5 kw,380v,50hz |

| Năng lực của lưỡi |

|

Động lực của xi lanh 6 bar |

| Tổng trọng lượng |

|

2000kg |

| Khối lượng tổng thể |

|

5800*3180*2400mm |

·Các đặc điểm chính

1) Áo cho bọt biển, PU linh hoạt.

2) Đường cắt: tốc độ cao, lưỡi dao răng.

3) Lưỡi dao cắt với tốc độ rung động cao, do đó nó làm việc nhanh hơn và sản phẩm sẽ trơn tru hơn.

4) Không có bụi, hoạt động đơn giản

5) Các bảng làm việc khác nhau để lựa chọn đáp ứng yêu cầu của bạn.

Thông tin đóng gói

Đối với việc đóng gói, có một đội ngũ chuyên nghiệp để tải hàng hóa. Và cũng, chúng tôi có một số hợp tác lâu dài với các đại lý vận chuyển người giàu kinh nghiệm của người vận chuyển. Vì vậy, đừng lo lắng,nó có thể tiết kiệm tiền và an toàn cho bạn.

·Dịch vụ sau bán hàng:

Các kỹ sư của chúng tôi có thể đến nước ngoài để điều phối lắp đặt, cho phép và đào tạo. chi phí cho chuyến bay và chỗ ở phù hợp

cộng với 60 USD mỗi ngày mỗi người sẽ được tính thêm. Máy của chúng tôi với bảo trì miễn phí suốt đời và khóa đào tạo miễn phí tại nhà máy của chúng tôi.Máy của chúng tôi đã được điều chỉnh và thử nghiệm trước khi giao hàng.

·Bảo đảm:

12 tháng bảo hành hạn chếbắt đầu từ ngày giao hàng, không bao gồm các bộ phận mòn.

chi phí vận chuyển cho các bộ phận được thay thế trong thời gian bảo hành phải được khách hàng chịu.

·Các điều khoản của Papent:

Tiền mặt 30% bằng T/T khi ký hợp đồng

70% được bảo lãnh bởi L/C được xác nhận là không thể đổi lại

Câu hỏi thường gặp

1)Q: Bạn là một nhà máy?

A:Vâng,Chúng tôi là một nhà sản xuất và làm cho các máy bọt từ năm 2006.

2)Q: Bạn sử dụng phần mềm vẽ nào?

A:Tự động CAD.

3)Q: Có phải kỹ sư của bạn có thể đến nhà máy của chúng tôi để lắp đặt máy?

A: Vâng, chắc chắn.

4)Q: Bạn có thể nhập các file DXF từ một nguồn khác?

Đáp: Vâng. Bất kỳ tập tin DXF nào cũng được chấp nhận.

5)Q: Máy dây nhanh khác có loại bỏ bụi và lọc. Máy này cũng có loại bỏ bụi?

A: Vâng, bao gồm nó.

6)Q: Các bạn đã bán đến những quốc gia nào?

A: Canada, Mexico, Brazil, Australia, Singapore, Malaysia, UAE, Yemen, Qatar, Algeria vv

7)Q: Những điều khiển an toàn trên máy là gì?

A: Có đáy khẩn cấp trên hộp điều khiển và máy cho tai nạn để ngăn chặn mahicne. Có hai hàng rào xung quanh khung cắt, máy sẽ dừng lại khi bạn mở hàng rào.